|

Grabhandler

Mission Models

S u m m a r y

|

|

Catalogue Number and Description: |

Mission Models

Grabhandler |

| Contents

and Media: |

One 92mm x 39mm steel tool |

| Price: |

USD$55.00 plus

local tax and shipping from Mission Models |

| Review Type: |

FirstLook |

|

Advantages: |

Solid construction;

easy and precise operation; marked in increments of inches and

millimetres; appropriate tool to work with either flat or three

dimensional materials; no assembly required; solidly packed. |

|

Disadvantages: |

Forward alignment pin may

interfere with the removal of larger "handles" |

|

Recommendation: |

Recommended for armour and

ship modellers; and scratch builders. |

HyperScale is proudly supported by

Squadron.com

We are continuously presented with modelling

masterpieces in print and online featuring photo-etched and resin

accessories.

However, there are still some jobs that are best

achieved using basic materials such as copper wire, brass profiles

or steel rod. I frequently use these materials for adding detail to

interior areas of aircraft and to specific parts of military models.

One of the most common tasks for armour modellers is

the fabrication of handrails, guard rails, tie-downs and grab

handles. Photo-etched parts are generally too flat for these items,

and plastic kit parts are often overscale, delicate and/or festooned

with difficult to remove seams. This is where metal wire, rod and

profiles come in very handy.

Typically, it is necessary to replicate between a

few and a whole pile of identical rails, tie-downs or handles for

any given armour modelling project. I have always used a pair of

needle-nose pliers for this job, but it is often a challenge to

create these parts exactly the same size.

Enter the Grabhandler.

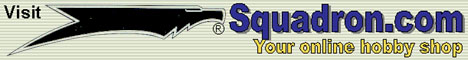

Mission Models' Grabhandler is a new tool

specifically for forming grab handles, as the name implies. The tool

is made from two small triangles of CNC steel aligned by three steel

pins. A plastic handle controls a steel thread which opens and

closes the steel jaws. A spring is installed to provide tension,

permitting the tool to remain open when required. The tool feels

very robust and high quality.

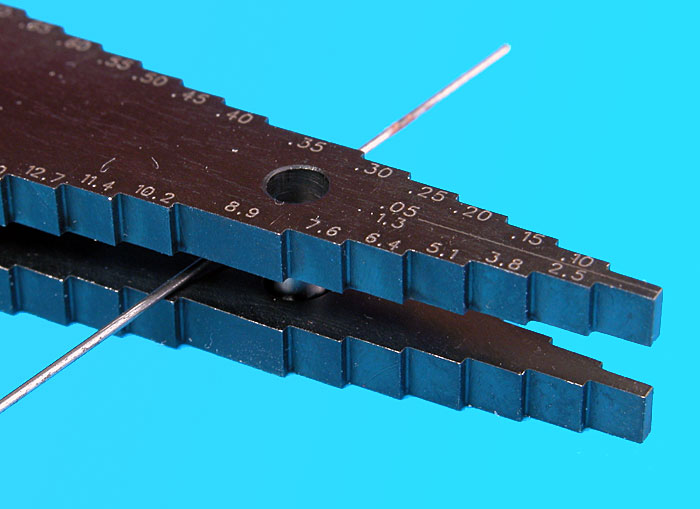

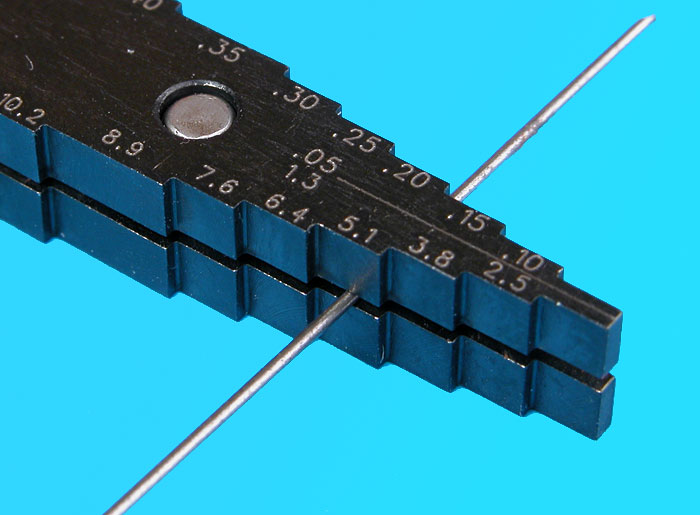

The triangular tool is serrated with 21 notches on

each side. The notches are marked in US (from 1/10" to 1.05") and

metric (2.5mm to 26.7mm) increments.

The operation of the tool could hardly be simpler:

-

Wind the handle

counter-clockwise to release the jaws

-

Insert material to

be bent into a handle according to the size required.

-

Turn handle

clockwise to close the jaws

-

Bend material on

both sides of the Grabhandler's serrations

-

Release the handle,

remove the newly formed "handle", and repeat as many times as

necessary

This will be a very quick, precise, reliable,

measurable and repeatable method for forming handles and other

similar shapes. The only problem I can anticipate is that the

forward locating pin might interfere with the removal of

newly-formed handles from the tool. Even so, some planning will

permit the largest handles to be threaded back through the tool

without actually separating the jaws.

I tested my Granhandler review sample out on some

steel wire - piano wire I think - which has proven difficult to bend

with other tools. The Grabhandler held the hard steel securely and

permitted quick and easy bending into a handle profile. It will be

even easier to work with more pliable materials such as brass and

copper.

At USD$55.00, this is not a low-priced tool.

However, "expensive" is in the eye (or perhaps the pocket) of the

purchaser.

If you are a modeller who is looking for a precise

and repeatable way to create handles or similar shapes, the

Grabhandler is the most specific tool I have seen to date for the

task.

Recommended for armour and ship modellers; and

scratch builders.

Thanks to Jon Tamkin from

Mission Models

the preview image and information

Etch Mate is available

from Mission Models

Website

Rreview Text and all Images Copyright © 2004 by

Brett Green

This Page Created on 23 May, 2004

Last updated

24 May, 2004

Back to

HyperScale Main Page |

Home | What's

New | Features

| Gallery |

Reviews | Reference

| Forum

| Search